50 Years of Experience in the Lubrication Field

INTZA Lubrication Systems has designed and manufactured reliable, robust quality, powered, pneumatic and manually operated pumped systems and accessories for more than 50 years. INTZA offer a comprehensive range for the controlled delivery of Oil and Grease fluids. Solutions include direct pump to point, spray application, Air-Oil, MQL – Minimum Quantity Lubrication and circulation systems.

Application areas include: Metal cutting / machine tools, Metal stamping & forging, deep drawing, die cutting, die lubrication. Oil and grease dosing for assembly lines and stations: chains and conveyors. Process industries, food and beverage including ‘dry’ lubrication for conveyor belts in the food industry, packaging, pulp and paper. Infrastructure, facilities and utilities equipment: power, wind turbine, water management sluice and lock gates, dockside equipment, cranes, metal cable lubrication, recycling. Mass transit: railway lubrication.

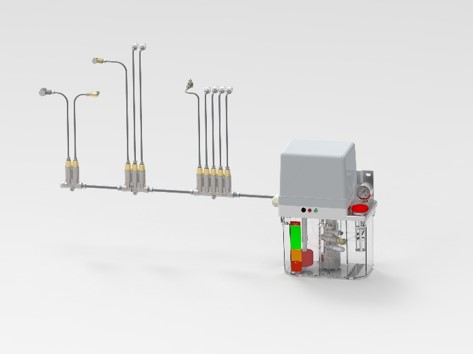

Single Line Lubrication Pumps, Valves and accessories

Lubrication pumps for use with oil and fluid grease.

- Available with and without inbuild controls.

- Pneumatic operation

- Electrically driven options: 24Vdc-115V-230V-230/400V

- Flowrate: 0,2 to 0,5 l/min

- Manual pump options.

- Supported by a range of volumetric injector and distribution values.

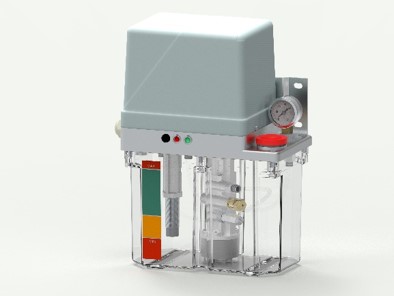

Dual Line Lubrication Solutions: Pumps, Valve and accessories

- Electric pumps flows: 1,8-3-7,5 l/hrr

- Reservoir: 2, 4, 7, 10, 20, 25, 30, 40, 60 kg

- Electrical motor: 230/400V

- Working Pressures 200 bar Max 400 bar

- Incorporated overpressure changeover

- Working Temperature -10 to +60 C

- Manual pumps for oil and grease.

- Flow 3 cm3/cycle

- Reservoir : 0.5,1.5, 5 litres

- Overpressure inverter incorporated

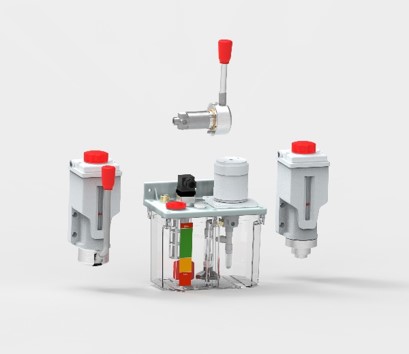

Progressive Lubrication Pumps

INTZA progressive systems are optimised for use in small and medium-sized machinery, combining robustness with an unbeatable quality-price ratio. INTZA offer a range of Electric and Pneumatic Piston pumps and Electrical Gear pump options.

Progressive Lubrication Distribution Valves and accessories.

Progressive Lubrication Distribution valves and accessories. Inductive sensor, electrical micro switch and excess pressure control indicators.

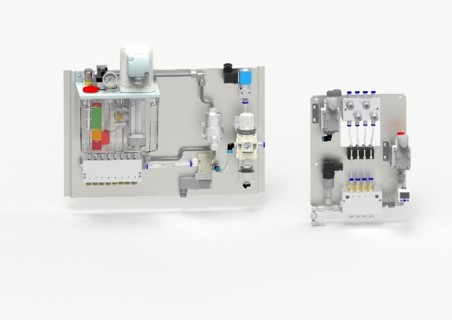

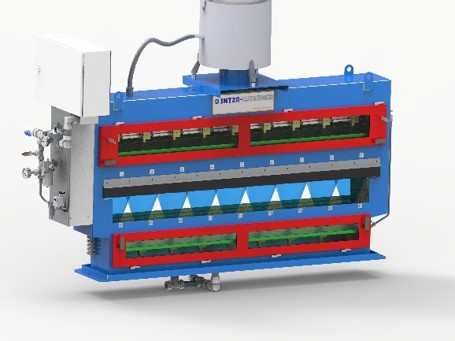

Air Oil Lubrication devices and panels builds

INTZA air-oil systems are essentially designed for application in the machine tool industry, (high-speed spindle heads, precision bearings and lubrication of closed gear boxes / spindles). Air-oil systems provide small and frequent amounts of lubrication to high-speed applications.

- Air-oil lubrication panels with electric or pneumatic pumps, high frequency micro pumps for lean oil control.

- Volumetric dosers and Electro-optic sensors and manifold blocks for secondary line pressures confirmation.

- For high frequency/low flow operations (from 4 to 30mm3/ stroke), pneumatic micro-pumps are more suitable, working up to a frequency (3Hz) for guaranteed lean oil-air lubrication.

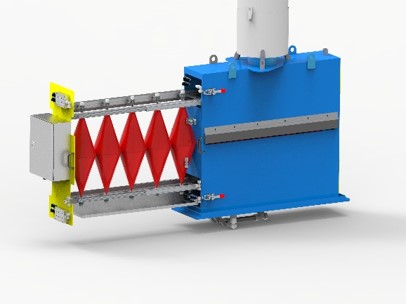

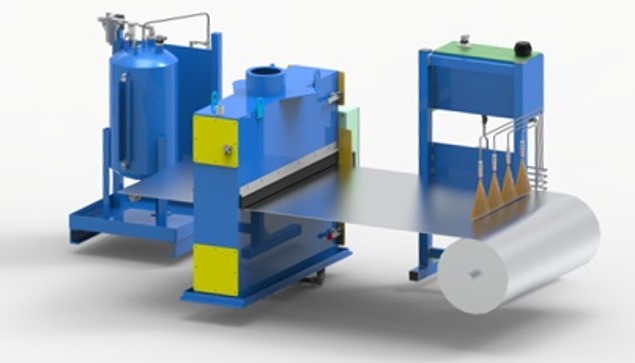

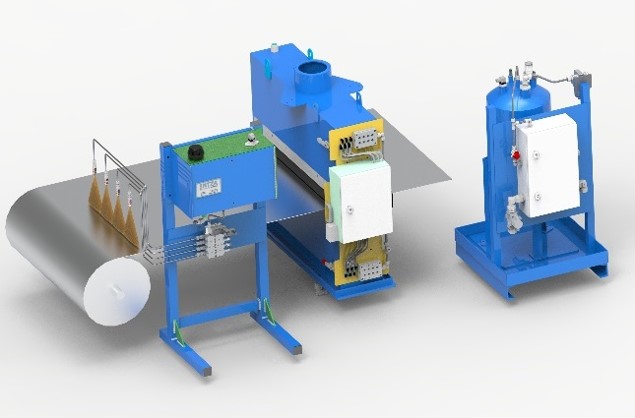

Lubricant Oil Spray Solutions

Lubricant oil spray solutions for industrial use help to keep systems correctly lubricated and oiled. Through the use of bespoke technology they can ensure the smooth running of vital systems ensuring greater uptime.

Oil Spray Solutions

- Pre-coating Steel Strip / coil for press and stamping lines.

- Controlled mist extraction.

- Controllable nozzle array.

- MQL Lubrication for saw blade and drill lubrication.

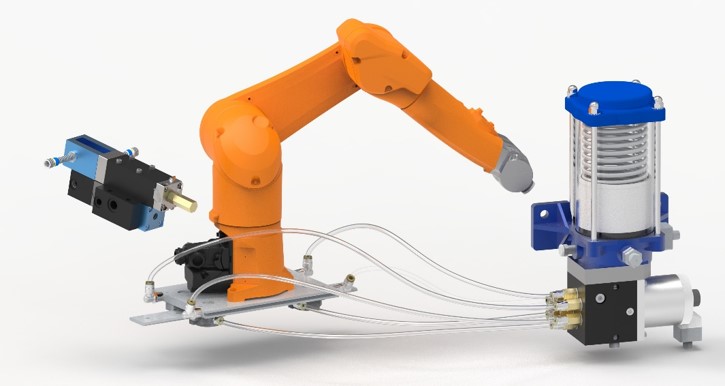

Multi Point Dosing System and Light / Conveyor Lubrication

INTZA oil and grease dosing systems are used on assembly lines for OEM series production lines e.g. special machines, robotic workstations, packaging / wrapping machines, automotive parts and products. The purpose of a dosing installation is to deliver timed and synchronised doses of lubricant to any mechanism in a continuously running production line.

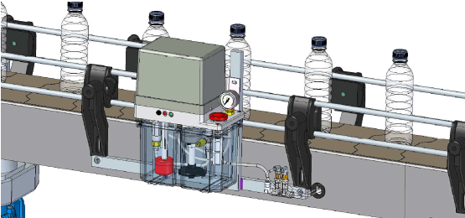

INTZA ‘dry’ lubrication systems substitute the use with water-soluble lubricants (water & soapy solutions) specifically developed to lubricate conveyor belts and the guides, reducing the friction, but avoiding surplus fluid contamination. Lubricants are applied volumetrically to loaded conveyor areas e.g. in bottling plants where the working zones can be heavily loaded.

Need help with your Intza system?

At Adams Lubetech we are experts in Grease and Oil lubrication equipment and systems including Intza, Abnox, Graco and Pulsarlube solutions.

Adams Lubetech is a major distributor of the Spanish manufactured Intza range of lubrication pumps, grease dispensing equipment and grease guns. We are also a distributor for Jaco, Manzel, Graco, Trabon, Lionoil, TTV, Codaitec, Botti, B Systems and Technolube products.

Whatever your specialised lubrication requirement is, Adams Lubetech is capable of providing you with the solution and supplying you with the right product. The Company has been registered to the Quality Management System BS EN ISO 9001 since 1993.

Find your local distributor

Adams Lubetech are represented in over 35 areas worldwide.

By contacting your local distributor you will get the best price and service from a local partner who understands your needs best.